INSIDIX is the representative of well known system manufacturers : NIKON for X-ray solutions and laser scanning, OKOS for acoustic microscopy solutions.

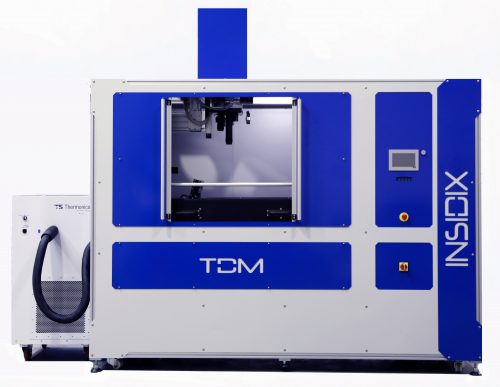

INSIDIX also designs and manufactures its own technology : the TDM

(www.tdm-3d.com).

State of the art, user friendly and easy to program, these equipments are designed to facilitate XRAY inspections.

XT V 130

The XT V 130C is a highly flexible and cost-effective electronics and semiconductor inspection system. The system features a 130 kV/10 watt Nikon Metrology manufactured source, a globally recognized open tube design with integrated generator, and a high-resolution imaging chain.

Through a series of factory and field upgrades, the end-user can configure these systems to their own needs with a higher power source, a rotating sample tray, automatic inspection software, a digital flat panel option, and the ability to add future-proof CT technology.

Benefits:

- Proprietary 30-130 kv micro-focus source with 2μm feature recognition

- True 72° manipulator tilting angle allows oblique viewing for easy inspection of internal features

- Large measurement area of 520×520 mm

- Intuitive joystick navigation drives real-time X-ray imaging

- Dual display for combined measurement and real-time analysis

- Low cost of ownership and maintenance with open-tube technology

- Safety as a design criterion

- CT and X.Tract (laminography) ready

XT V 160

The XT V 160 is specifically designed for use in production lines and failure analysis laboratories. With a precision joystick, system users control the 5-axis sample manipulator. Real-time X-ray allows users to intuitively navigate complex printed circuit boards and electronic components and quickly trace defects. In automated inspection mode, samples can be inspected at highest throughput.

Benefits

- Leading proprietary micro-focus source technology

- Fast automated component inspection through customizable macros

- Intuitive joystick navigation drives real-time X-ray imaging

- 4K Ultra HD display for combined measurement and real-time analysis

- Low cost of ownership and maintenance with open-tube technology

- Safety as a design criterion

- CT and X.Tract (laminography) ready

XT H 225-450

The XTH (horizontal) systems allow the inspection of bigger samples, with high resolution. The tomography is really fast thanks to CT ultrafast mode (1/4 faster than conventionnal mode).

Applications: plastics processes, metal processes, material research, …

ModelMaker H120 - Ultra-Fast High-Definition 3D Scanning

Blue laser technology, ultra-fast data rates, specially developed Nikon optics and the ability to measure the most challenging parts in fine detail combine to enable the cutting-edge ModelMaker H120 to push the exacting boundaries of handheld laser scanning productivity.

MCAx S - Delivering a New Level of Portable Measurement Performance

MCAx S is a precise, reliable, easy-to-use CMM able to measure around and even inside large parts without constraints. Accuracy, capability and portability make it an optimal inspection companion in the metrology lab, on the shop floor or in the field.

ModelMaker H120 and MCAx S System

Measure challenging materials with exceptional detail at high speed directly on the shop floor. Pairing the ModelMaker H120 laser scanner with the MCAx S range of precision portable CMM arms delivers unparalleled freedom to accurately investigate production quality in all industrial application.

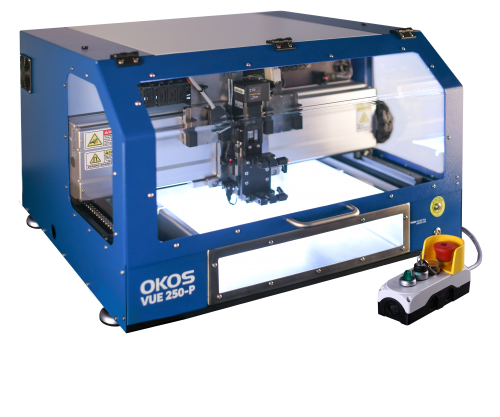

SAM Vue 250 P

The SAM Vue 250 P is the most compact model of the OKOS brand. Affordable, flexible and well designed, the Vue250P is equipped with state of the art software/hardware combination, meeting the challenges of today industries for failure analysis (FA).

Key words : cracks, delamination, defects, debondings, voids.

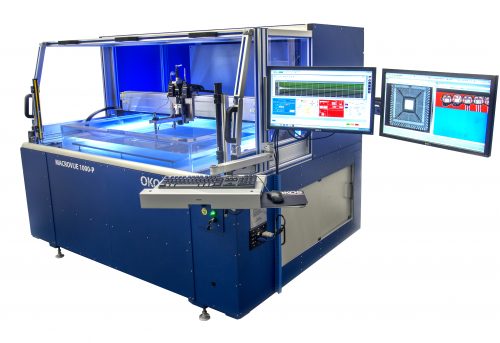

SAM Vue 400 P

The acoustic microscope Vue 400 P is designed for failure analysis. This microscope is equipped the last innovations in term of transducers, signal processing and image treatment.

Key words : cracks, delamination, defects, debondings, voids.

NDT CF 300

This 5 axes scanner allows to perform an inspection on different kind of materials (plastics, metals, alloys, …). Highly used in the research field and by universities, the CF300 is user friendly and can be customized according to applications.

Autres machines ultrasons

OKOS brand proposes other equipments, for solar panels inspection for example.

For any question, contact us.

All TDM machines

INSIDIX proposes four different TDM models. The choice between these machines depends upon the size of the samples to analyze, the max/min temperatures to reach for test and the applications.

The four models are :

- TDM Table Top

- TDM Large Scale

- TDM Compact

- TDM Compact 3

More information, https://www.tdm-3d.com/